We have the plastic container for traceable and sanitized produce ideal for all your needs, as we offer different sizes and formats. By implementing the smart HB packaging solution in the distribution of your fruits, vegetables, and greens, you keep the food fresh, reduce damage and make much better use of the space during the transportation.

According to the WHO, about 600 million people worldwide get sick after eating contaminated food every year. So, this brings up an extremely important issue for the distribution of fresh food: cross-contamination.

In short, this contamination is about the transfer of pathogenic microorganisms between different foods. That is, a food that is already in advanced ripening process can contaminate a whole load, if the containers do not have the proper protection to avoid this contact.

In this regard, for example, we have the case of transporting bananas with other foods. Just to illustrate, the banana produces a gas called ethylene, which stimulates ripening, including other fruit.

However, HB containers have improved ventilation, which helps to reduce the accumulation of ethylene gas. Furthermore, Food Safe plastic protects the food from contamination and with its resistance protects against external impacts, in addition to the rounded corner design that protects from internal friction during the transport.

Less damage to FLVs because the container is anatomical and has stable stacking.

Gain of space in the return, as the containers can be folded.

More deliveries by the perfect fit and therefore allow super stacking.

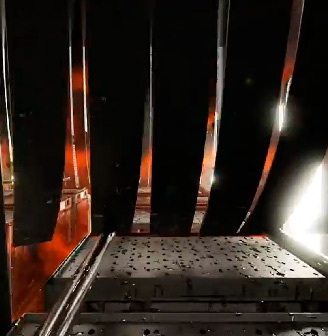

The containers undergo automated sanitization and then are attested in each cycle.

Each container has a unique identification code and a label holder that allows control.

It allows homogeneous circulation of air, prevents overheating, and also dissipates ethylene gas.

Produced in 100% virgin and non-toxic Food Safe plastic, recyclable and protects from contamination

In contrast to HB CONTAINERS, with the transport in CARDBOARD BOXES, food is at risk of contamination in several ways:

And the same happens in wooden boxes.

HB RETURNABLE PLASTIC CONTAINERS have automated sanitization before the start of the food delivery cycle, so any waste and chances of contamination by their use are eliminated. The sanitization is performed according to the requirements of HACCP and ANVISA and attested by laboratory reports. These tests, in turn, involve the microbiological assessment of the containers surfaces for coliforms, bacteria, molds, yeast, and salmonella.

The HB returnable plastic container for FLVs can go from the field to the gondola avoiding tipping from one container in the field to another in the DC and again in the POS, thus maintaining the integrity of the products and generating time and productivity gains.

In addition, our containers arrive at the retailer ready for exhibition, as they become beautiful displays on the shelves of the point of sale.

Undeniably, this is also a sustainable choice for the distribution of your products. This is because each HB returnable plastic container is sanitized with only 160ml of treated water.

In addition, 90% of the water is reused in the process, before going through the treatment of effluents and returning to nature.

The equipment has the capacity for the perfect sanitization of up to 4 thousand containers per hour. They are energy-efficient and consequently add much more sustainability to the supply chain. Still, in addition to all this efficiency, even the heat generated in the process is reused.

The containers are made of fully recyclable Food Safe plastic and reduce damage to products by up to 96% and food waste by 35%, in the dynamics of the food distribution.

In addition, there is a 60% reduction in CO2 emissions due to the perfect stacking and the folding parts in the return, mainly allowing the gain in cubic capacity with fewer trips and more deliveries.

Therefore, because they are not made of cardboard, the HB containers reduce by 86% the solid waste discarded in nature.

Move to Sustainability with HB SMR

Outer Dimensions L x W x H: 400 × 300 × 160 mm

Interior Dimensions L x W x H: 362 × 3262 × 151.5 mm

Usable Height Inside: 142.5 mm

Capacity: 6 kg

Stackable Load: 150 kg

Volume: 14l

Folded Height: 36 mm

Temperature Resistance: -20ºC to 40ºC

Outer Dimensions L x W x H: 600 × 400 × 120 mm

Interior Dimensions L x W x H: 568 × 369 × 108 mm

Usable Height Inside: 97 mm

Capacity: 10 kg

Stackable Load: 300 kg

Volume: 22l

Folded Height: 36 mm

Temperature Resistance: -20ºC to 40ºC

Outer Dimensions L x W x H: 600 × 400 × 180 mm

Interior Dimensions L x W x H: 568 × 368 × 168 mm

Usable Height Inside: 156 mm

Capacity: 15 kg

Stackable Load: 300 kg

Volume: 35l

Folded Height: 36 mm

Temperature Resistance: -20ºC to 40ºC

Outer Dimensions L x W x H: 600 × 400 × 230 mm

Interior Dimensions L x W x H: 568 × 369 × 218 mm

Usable Height Inside: 206 mm

Capacity: 20 kg

Stackable Load: 300 kg

Volume: 45l

Folded Height: 36 mm

Temperature Resistance: -20ºC to 40ºC

Outer Dimensions L x W x H: 1200 × 1000 × 800 mm

Interior Dimensions L x W x H: 1120 × 920 × 660 mm

Capacity: 750 kg

Stackable Load: 7000 kg

Volume: 720 l

Folded Height: 298 mm

Temperature Resistance: -20ºC to 40ºC

Envie no WhatsApp